Week 2 was the true planning week for the project. While the first week offered a good start by focusing our group on copper/water heat pipes and their use in electronics cooling, the rest of the project has completely changed.

From the outset, we wanted to conduct a materials comparison as a challenge to not only observe physical properties but to describe them with an equation related to each materials effectiveness in transferring heat.

Initially, we thought to compare working fluids, since they are the most easily obtained and replaced. In addition, we would have loads of data on surface tension, viscosity, heat of vaporization, and other crucial properties at our disposal. However, after looking at various fluids in the comparable temperature range of water, which included acetone, methanol, and toluene, we decided that it would be too dangerous to be heating and vaporizing these materials in the workshop environment.

Our group then switched the focus to the pipe metal itself. We could easily compare a few metals such as aluminum, copper, and steel to see which was most effective at transferring heat. The major advantage here is that we already knew what the results of our analysis would be. By using each materials properties to calculate its Merit Number, which describes its effectiveness at certain temperatures, we could easily see that copper was the best metal to use. However, when it came time to compile a materials list, we had trouble finding steel and aluminum pipes that had the correct threading to be secured with an endcap. In addition, those materials could not easily be soldered, thus we decided to change course yet again.

We finally decided upon comparing wicks. The wick is an internal structure that facilitates the transport of condensed vapors back to the bottom of the heat pipe. While they are not necessary for vertical applications (gravity does all of the work), they are needed in horizontal and near-horizontal applications. Many electronics require heat pipes to be installed in this orientation (for example in laptops), so it would be perfectly applicable to our area of focus.

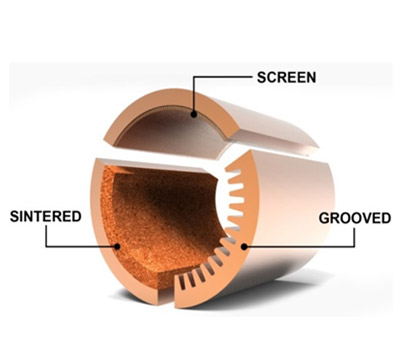

Expensive wicks can be made out of channeled grooves and sintered metal, but we wanted to focus on metal mesh. Metal mesh wicks are cheap, easily inserted and removed, and can be purchased in small quantities, all important factors for our analysis. For our analysis we will be using aluminum screen mesh. This mesh can simply be rolled up and inserted into the heat pipe as long as it is thoroughly wetted and presses up against the walls of the heat pipe. It is important that the screen mesh be wet, else it will not be able to facilitate the movement of condensed vapors back to the bottom of the pipe. This will create a lack of working fluid, causing the heat pipe to not work properly.

|

| Credit: www.celsiainc.com |

Three common wick structures used in heat pipes

However, the main reason we wanted to conduct our analysis on wicks is because we didn't know which would be most effective. When conducting literature study we encountered many tests and experiments detailing the efficiencies of sintered metal wicks and grooved channels, which are the newest, most cutting edge wick technologies. But in all of our study not once did we find testing results on wire mesh wicks.

This is what makes our analysis truly beneficial. Unlike what we expected to do for comparing metals and working fluids, we are not studying some known factor with some end conclusion in mind. We honestly do not know which wick size will turn out to have the fastest rate of heat transfer. This allows us to follow the scientific method by making educated guesses and examining results with nothing to compare them to. Our analysis will then be unique and useful to people who choose to forego expensive commercial technologies in favor of the DIY method of improving and modifying electronic devices.

The next step is to purchase all materials and begin construction of the heat pipe, which should begin by next week. The updated project proposal detailing how we plan to compare the different wicks can be found under the project proposals tab below the original proposal. We remain on schedule as we head into week 3.

-- Alec, Tran, Matt, and Shjon

No comments:

Post a Comment